MEDIVATORS INC. MEDIVATOR VERISCAN LEAK TESTER - medivator

» Steam inlet piping complete with drip leg, thermostatic steam trap and blow-off valve to prevent condensate accumulation during start-up and shutdowns.

» The EZ Heater and all components are rated for 150 psig [10 barg]. The EZ Heater is rated at 195 psig [13.4 barg] at 400°F [205°C].

» The EZ Skid can be provided with an optional internal re-circulation pump, designed to handle high turn-down or rapidly varying flow rates. The pumps can also be provided for plant re-circulation, to maintain the water piping system at design temperature.

» Paddle wheel flow sensor is used to measure water flow, serving as a protective device for no-flow condition. This also enables flow logging through the Hydro-Thermal controller.

» Provided with pressure gauges for the steam and water piping. Isolation valves provided, along with steam siphon on the steam lines

» Provided with an automatic on/off steam valve, which isolates steam when the unit is disabled. This is a high-performance

» Units are equipped with electro-pneumatic positioners (Fisher DVC6200AC on 3”, 4”, and 6” units; DVC2000AC on smaller units).

The EZ Skid is an integrated, compact pre-engineered heating system, utilizing the direct steam injection EZ Heater. All components needed for correct application are included; simply connect to plant utilities: steam, water, air and power.

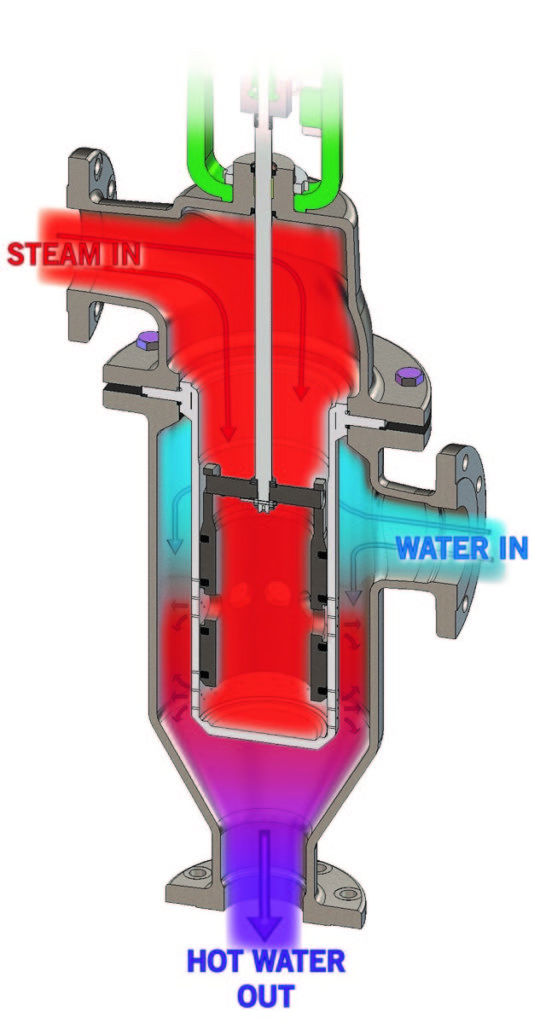

» Patented design for effective heat transfer, utilizing internal modulation for precise temperature control and predictable results. See “EZ Heater Product Brochure” for further details.

Process Systems Mixers Heat Transfer Systems Stainless Steel Tanks and Kettles Brewery Equipment Hoses and Strainers Vacuum Conveyor Valves

Hydro-Thermal proprietary controller is designed to respond to a wide range of flow conditions with a high degree of accuracy. The controller is designed as a dedicated control for the EZ Skid, with some plant interface possible. See “SMART Controller” for further details.

» Some components utilize carbon steel bodies with stainless steel trim (larger check valves, automatic on/off steam valves, pumps, etc).

» Includes check valves on the steam and water supply to assure that under upset conditions, water will not enter the steam piping or steam will not enter the upstream water piping. Check valves are spring-assisted silent check valves.

Accuracy of temperature control depends on flow turn-down and flow rate variation. Highly variable or rapidly changing flows require a re-circulation pump and fast response features. We can recommend the most cost-effective controls for your application.

Neil

Neil

Neil

Neil