Lenovo ThinkPad Thunderbolt 4 WorkStation Dock - ... - 40b00300us

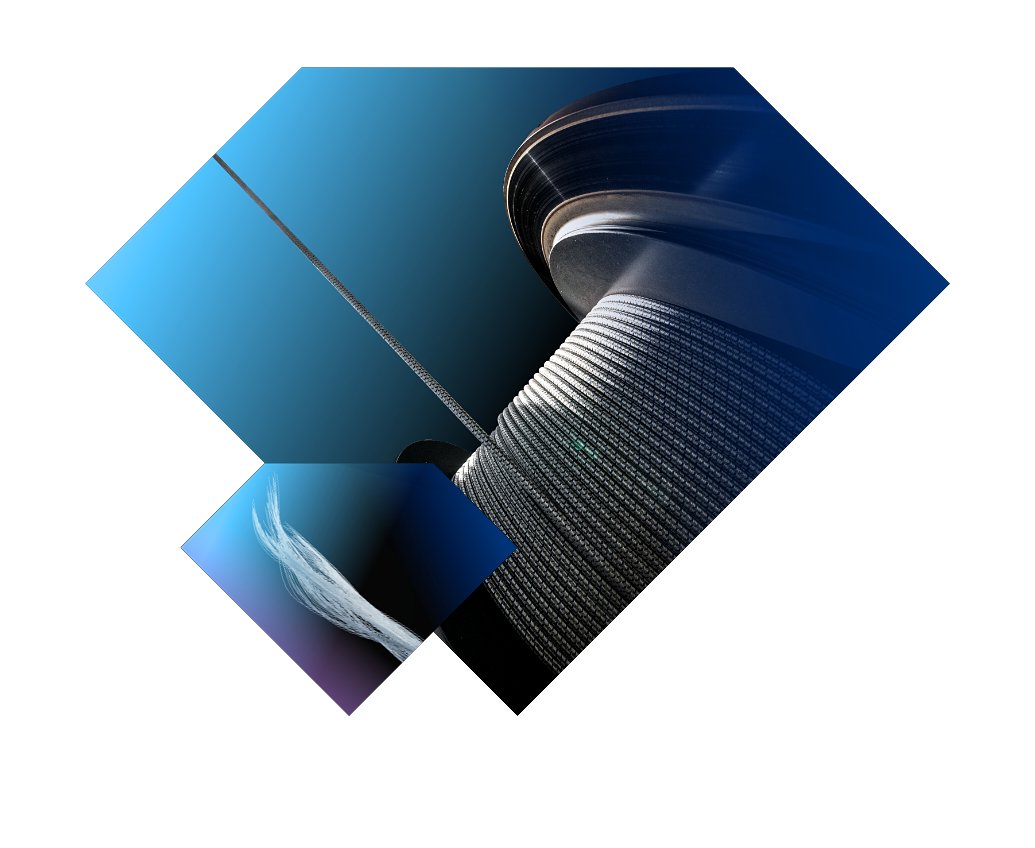

Unlike other fiber manufacturers, we rigorously test the minimum breaking strength not only of our fibers, but also in rope and sling constructions.But there is more to it. Rope strength at moment of purchase is only one datapoint. What matters more is strength over time, as this relates to the reliability of your operation. How does strength evolve over time. This is the most important factor and we at Dyneema® have put a lot of effort into understanding and improving behavior of our fibers.

Here we evaluate external abrasion at actual conditions – ideal for measuring the impact of sharp angles, sheaves, and metal surfaces when operating your winch or crane.

The world's strongest fiber™ Home Sectors Design with Dyneema® Experience More Sustainability Where to Buy Contact Us Privacy Policy Terms and Conditions

Dyneema® fibers are renowned the world over for outstanding quality, consistency, and performance – as recognized by our array of third-party certifications covering the full production processOur team of experts can work with you to support you in getting your winch or crane design with Dyneema® certified by thirt-partIs verification the same as certification?The simple answer is “no.” Verification statements confirm the initial holding capacity of a rope or sling, but don’t give information on its suitability for the intended lifting operation. Certification, on the other hand, confirms not only the initial holding capacity but also its lifetime holding capacity – determining the useful service life in its planned operation.In short, if you want fit-for-purpose, durable, and sustainable heavy lifting ropes, certificates are the documents for you.

Our team of experts can work with you to support you in getting your winch or crane design with Dyneema® certified by thirt-partIs verification the same as certification?The simple answer is “no.” Verification statements confirm the initial holding capacity of a rope or sling, but don’t give information on its suitability for the intended lifting operation. Certification, on the other hand, confirms not only the initial holding capacity but also its lifetime holding capacity – determining the useful service life in its planned operation.In short, if you want fit-for-purpose, durable, and sustainable heavy lifting ropes, certificates are the documents for you.

Aa58 flight status

Here we evaluate external abrasion at actual conditions – ideal for measuring the impact of sharp angles, sheaves, and metal surfaces when operating your winch or crane.

Construction and manufacturing are all about teamwork – and we’re on your side. To optimize your crane lifting operations with Dyneema® and benefit from custom advice, don’t hesitate to reach out to our experts.

Ua5821

In turn, this makes every construction and manufacturing lift faster and more cost efficient. Plus, durable Dyneema® fiber reduces the number of rope changes needed, decreasing downtime and increasing crane availability.

At least 80% lighter than steel crane wire ropes at the same strength, crane ropes made using our ultra-high-molecular-weight polyethylene (UHMWPE) take crane lifting capacity, technology, and performance to new heights.

UA5865

Our premium crane rope partners are dedicated to manufacturing and supplying high-performance hoist and cable solutions with Dyneema® fiber – delivering ultimate strength plus safety, efficiency, and more. Looking for extra peace of mind? Our crane rope manufacturing partners are happy to offer the service and maintenance packages you need to keep your operations running smoothly and safely, day in, day out.

And there’s more good news: opting for bio-based Dyneema® fiber gives you all the benefits of conventional Dyneema® with a carbon footprint that’s 90% lower than generic HMPE. Certified by the International Sustainability and Carbon Certification (ISCC), our world-first bio-based alternative is a simple and reliable way to make every lift greener.For a big impact with a small footprint

In short, if you want fit-for-purpose, durable, and sustainable heavy lifting ropes, certificates are the documents for you.

UA926

Ua 58 terminal

But there is more to it. Rope strength at moment of purchase is only one datapoint. What matters more is strength over time, as this relates to the reliability of your operation. How does strength evolve over time. This is the most important factor and we at Dyneema® have put a lot of effort into understanding and improving behavior of our fibers.

The simple answer is “no.” Verification statements confirm the initial holding capacity of a rope or sling, but don’t give information on its suitability for the intended lifting operation. Certification, on the other hand, confirms not only the initial holding capacity but also its lifetime holding capacity – determining the useful service life in its planned operation.In short, if you want fit-for-purpose, durable, and sustainable heavy lifting ropes, certificates are the documents for you.

Whether operators are preparing, installing, or using crane cables, safety is paramount. Replacing steel wire ropes with lightweight Dyneema®-based hoisting rope solutions is a simple way to make handling safer, easier, and more comfortable on site. Better yet, ropes made with Dyneema® fiber don’t create dangerous fishhooks, making reeving and handling safer still.What’s more, thanks to the durability of Dyneema®, crews can rely on a high level of safety over a longer service life than is offered by either steel or generic synthetic crane lifting solutions.

Here’s where the Dyneema® difference really comes into play. While the extreme weight of traditional steel ropes eats significantly into a crane’s maximum lifting capacity, lightweight crane cables made with Dyneema® means operators can safely use more of their crane’s lifting potential where it matters: on the payload itself.In turn, this makes every construction and manufacturing lift faster and more cost efficient. Plus, durable Dyneema® fiber reduces the number of rope changes needed, decreasing downtime and increasing crane availability.

Did you know Dyneema® delivers the lowest carbon footprint per unit strength of all high-performance fibers? Not only is Dyneema® fiber manufactured using 100% renewable electricity, but its low weight also enables less energy use in transport and operations. What’s more, Dyneema®-based crane ropes and hoists have a longer service life than alternatives, delivering greater resource efficiency.

UA59

UA58plane type

Thanks to Dyneema®’s versatility, there’s a fiber for every lift, for greater strength, safety, and sustainability on site.

Reliably longer service life enables less resource consumptionLow weight means less energy useBio-based Dyneema® available

Ua58seat map

From dusty construction sites to pristine cleanrooms, crane cables and hoisting ropes made with Dyneema® fiber bring unmatched strength plus a wide range of other performance benefits. Rust free and self-lubricating, Dyneema®-based crane ropes are the ideal solution for indoor hoisting in sensitive cleanroom environments since, unlike with steel cables, there’s no risk of contamination from steel particles or oil.

What’s more, thanks to the durability of Dyneema®, crews can rely on a high level of safety over a longer service life than is offered by either steel or generic synthetic crane lifting solutions.

Crane ropes made with Dyneema® are uniquely strong – but there’s much more to it than that. Dyneema® fiber is carefully engineered to offer a solution that at least meets the reliability of steel wire rope.

When loads are heavy and deadlines are tight, the last thing crane operators need is a weighty steel wire hoist rope. Instead, it’s time to turn to synthetic crane cables – but not just any synthetic crane cables. To ensure reliability, the only proven solution is crane hoisting ropes made with Dyneema®, the world’s strongest fiber™.At least 80% lighter than steel crane wire ropes at the same strength, crane ropes made using our ultra-high-molecular-weight polyethylene (UHMWPE) take crane lifting capacity, technology, and performance to new heights.

The world’s strongest fiber™ offers so much more than just strength. For more than 10 years, we’ve been proving the all-round power of Dyneema® fiber in end-use applications, thanks to our suite of proprietary, state-of-the-art testing equipment.Unlike other fiber manufacturers, we rigorously test the minimum breaking strength not only of our fibers, but also in rope and sling constructions.But there is more to it. Rope strength at moment of purchase is only one datapoint. What matters more is strength over time, as this relates to the reliability of your operation. How does strength evolve over time. This is the most important factor and we at Dyneema® have put a lot of effort into understanding and improving behavior of our fibers.

Is verification the same as certification?The simple answer is “no.” Verification statements confirm the initial holding capacity of a rope or sling, but don’t give information on its suitability for the intended lifting operation. Certification, on the other hand, confirms not only the initial holding capacity but also its lifetime holding capacity – determining the useful service life in its planned operation.In short, if you want fit-for-purpose, durable, and sustainable heavy lifting ropes, certificates are the documents for you.

Neil

Neil

Neil

Neil