Humangenetik Berlin · MVZ Humangenetik Berlin - 8872900

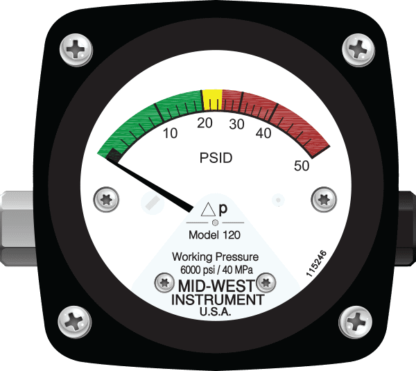

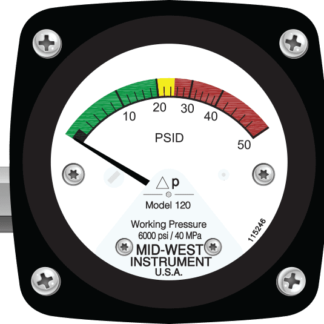

DP Ranges: PSID, Bar, Kpa, Dual Scale Body Materials: Aluminum or 316L Stainless Steel Dial Types: 3-1/2″ & 4-1/2″ Round Uni-Directional Round Anodized Aluminum housing assembly Seals & Diaphragm Materials: Buna-N, Viton Carbon or Stainless Steel Pipe Mount Kit (Pipe Mount option not available for Model 122) (Pipe Mount option not available with C or D switch option) Liquid Fill or Maximum Follower Pointer (Can not combine Liquid Fill with Maximum Follower Pointer options) Wall Mount Kit (Not available with back connections) (Wall Mount option not available with C or D switch option) Connections: 120/122(1/4″FNPT) and 120(1/2″FNPT)

Mid west instrument 120sa 10 oomanual

Mid-West Backflow Gauges are capable of performing all known test procedures including those recommended by: ABPA, ASSE, AWWA, CSA, FCCC and HR-USC, NEWWA and UF-TREEO

Mid westBackflow Test Kit calibration

Mid-West differential pressure gauges are designed to measure pressure drop across Filters, Strainers, Separators, Valves, Pumps, Chillers, etc. as well as for local flow indication and control. Basic gauge function is to measure the difference in pressure between two points in a system, the differential pressure results are displayed on the gauge dial.

Midinstruments

We use cookies to make our services work and collect analytics information. To accept or reject analytics cookies, turn on JavaScript in your browser settings and reload this page.

Mid westBackflow

Dial Types: 3-1/2″ & 4-1/2″ Round Uni-Directional Round Anodized Aluminum housing assembly housing assembly, Non-Indication differential pressure switches available. Seals & Diaphragm Materials: Neoprene, Teflon, Ethylene Propylene and Perfluoroelastomer Connections: 7/16″-20 Straight thread “O” ring port Other Options: Reversed high/low process connections, Oxygen Cleaning, Stainless Steel Tags and more… Electrical Switches: 1 & 2 switch std, Class 1 Div. 1 & Div 2, Explosion Proof

Mid-West Piston Type: Model 120 ± 2% or Model 122 ± 5% Full Scale Accuracy. Piston type gauges are primarily designed for liquid applications. Differential Pressure is sensed by the movement of a precisely ground floating piston/magnet in a precision bore against a calibrated spring. Any variation in pressure on either side of the piston/magnet will cause the magnet to move proportionally to the change in differential pressure. A rotary pointer magnet located close to the internal magnet, but outside the pressure housing, follows the movement of the piston magnet and indicates differential pressure on the dial. Piston type DP gauges exhibit a slight amount of bypass as the fluid crosses from the high to the low pressure port. Due to precision sizing of piston and body bore, leakage across the piston will not exceed 15 SCFH air at 100 PSID at ambient conditions.

Warning: Cancer and Reproductive Harm – www.P65Warnings.ca.gov For complete information on Proposition 65, please read this informational PDF or visit www.p65warnings.ca.gov

120-AA-00-OO 3000 P.S.I.G. Working pressure, aluminum body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna-N, seals, 2½” round dial, ¼” FNPT back connections, “engineered plastic” gauge, case with shatter-resistant acrylic lens. Accuracy ± 2% F.S.* (Ascending)

Mid-West differential

Mid west instrument 120sa 10 ooreview

120-SA-00-OO 6000 P.S.I.G. Working pressure, 316L S.S. body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna-N seals, 2½” round dial, ¼” FNPT back connections, “engineered plastic” gauge case with shatter-resistant acrylic lens. Accuracy ± 2% F.S.* (Ascending)

All Model 120/122 differential pressure gauges either conform to and/or are designed to the requirements of the following standards:

Neil

Neil

Neil

Neil