Dyson DC33 Vacuum Cleaner Motor Fancase Seal YDK - fancase

Just browsing on the net and on eBay saw thus hoist. I just thought it may be useful to some members at a fairly low cost. It does need a good think about the base load fixing but there are ways round this but I can see it lifting a chuck or rotary table etc.

As a young soldier in Germany I was a weapons repair chap working on Chieftain Tanks, we were issued the Haltrac for removal and replacement of the breech block, it was also sold for moving trees, towing cars etc !!

Like Mike Woods, I saw one of the Lidl ones in my local store yesterday. Of course an overhead beam is needed for this type. The crane type would be great if there was enough room for it to sit between two machines. Making a trolley for one is possible if great care was taken in the design and manufacture.

Search for: Home › Forums › Workshop Tools and Tooling › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post Warwickshire Show, to go or not. Started by: Lathejack in: Exhibitions, Shows and Club Events 10 13 17 October 2024 at 16:56 Vic New guy from Norway, planning a Bonelle grinder 1 2 Started by: Fulmen in: Introduce Yourself – New members start here! 18 46 17 October 2024 at 16:49 Fulmen Jekyll’s “Pendulous” Engine c 1870 1 2 Started by: JasonB in: Stationary engines 11 33 17 October 2024 at 16:39 JasonB Is it safe to paint humbrol / revel enamel paint over car spray paint? Started by: Simon Robinson 4 in: The Tea Room 10 12 17 October 2024 at 16:37 Dave Wootton Diesel 1 2 3 Started by: Vic in: The Tea Room 23 66 17 October 2024 at 16:30 Macolm Pultra model P 1 2 Started by: mark smith 20 in: Manual machine tools 8 30 17 October 2024 at 16:09 mark smith 20 M&W Microstat Micrometer Started by: peak4 in: General Questions 3 12 17 October 2024 at 15:49 peak4 What did you do Today 2024 1 2 … 16 17 Started by: JasonB in: The Tea Room 62 408 17 October 2024 at 13:52 Roderick Jenkins Stuart Dynamo 1 2 3 4 Started by: Steve Rowbotham in: Beginners questions 13 77 17 October 2024 at 12:05 duncan webster 1 A question of design Started by: ian Holdsworth in: Locomotives 7 9 16 October 2024 at 23:41 duncan webster 1 Creworks Chinese Mini Lathe – interesting 1 2 Started by: Lee Cooper in: Manual machine tools 15 34 16 October 2024 at 22:50 Vic Renishaw touch probe bits 1 2 Started by: gerry madden in: Electronics in the Workshop 9 28 16 October 2024 at 21:14 Michael Gilligan Baldwin Gasoline Mechanical – a bit more progress Started by: Steve Addy in: Work In Progress and completed items 3 5 16 October 2024 at 18:04 Steve Addy Filament Dryers Started by: Colin Heseltine in: 3D Printers and 3D Printing 6 10 16 October 2024 at 16:16 Roderick Jenkins Space X booster landing Started by: norm norton in: The Tea Room 17 22 16 October 2024 at 10:37 Bazyle 3 1/2 juliet 1 2 Started by: 474564 in: Help and Assistance! (Offered or Wanted) 9 33 16 October 2024 at 10:30 noel shelley My mini lathe won’t latch on Started by: Paul McDonough in: General Questions 8 14 16 October 2024 at 10:20 Paul McDonough It’s alive! Started by: Dave S in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools 4 6 15 October 2024 at 21:59 Nicholas Farr Hemingway engraving tool 1 2 Started by: Mike Waldron in: Manual machine tools 9 30 15 October 2024 at 20:51 Andrew Tinsley Myford Super 7 headstock taper bearing Started by: Andrew Moyes 1 in: Manual machine tools 5 6 15 October 2024 at 19:53 Neil Lickfold Warco mill lubrication 1 2 Started by: Peter Venn in: Workshop Tools and Tooling 15 44 15 October 2024 at 15:24 Brian Wood Macro-photography 1 2 … 19 20 Started by: Raphael Golez in: Related Hobbies including Vehicle Restoration 65 496 15 October 2024 at 13:36 bernard towers Wardlaw Museum Started by: Michael Gilligan in: Stationary engines 5 5 15 October 2024 at 12:05 Dave Daniels Depth of Cut advice needed please – Warco WM16b Started by: Robert Bowen-Cattry in: Beginners questions 5 13 15 October 2024 at 11:48 Robert Bowen-Cattry Mounting boring bar in the lathe Started by: Mick Bailey in: Workshop Tools and Tooling 7 14 15 October 2024 at 09:15 David George 1 Viewing 25 topics - 1 through 25 (of 25 total)

Thats an interesting device but waay to big and heavy for in workshop use. Basically its an engine crane on a rotating pillar. Looked at one like that for a project sometime back. As I recall things it was good for something over a ton at 5 ft jib extension.

If you have a look in youtube there are a number of videos about collapsing car lifts bolted to slabs. There are many things that can cause a bolted plate joint to pull off a slab.

In respect of the Haltrac hoist, an amazing bit of kit, have lifted numerous engines in and out of cars with it, I think I still have it somewhere must be 50 years old now. Dave W

The Haltrack lock is just a cam that presses on the rope squeezing it between the sheave and the top assembly cross bar. The cam action geometry makes it self tightening. The rope passes through a lever on the cam so it is pulled up when the rope is pulled at >45 degrees which means for safety you cannot be underneath it. When I was lifting my minor mill drill this angle meant I was pulled across the floor

The device shown has only a small baseplate, so the load, via the baseplate imposes a large vertical tensile load onto the floor fixings, Depending upon the orientation of the load, the load could all be borne by only one fixing.

I could not find that specific one but noted that none of the identical looking ones had no CE marking. This means that it is technically illegal to sell or use them. There is no assurance that they are designe or manufactured correctly. There is no indication that they are not OK, but I would not push the limits or get any part of my body under a load.

My pal has a small Parkside (Lidl) electric cable hoist mounted on rails fixed to his garage roof joists (suitably reinforced) above his Mikron mill to lift machine vice, table extensions etc. 125kg direct lift, but can be increased to 250kg with pulley. I have just returned from my local Lidl before reading this post and noticed a few these hoists are still available from the MoL offer a week or so ago. Probably not recommended for your average shed though, unless you want a roof lowering feature or are confident in your shed strengthening skills. I didn't look at the price, but understand that they were on offer at £59.99 earlier in January

There are several similar "block and pulley" items on ebay like "mannesmann rope hoist" a random one is http://www.ebay.co.uk/itm/Mannesmann-Rope-Hoist-180-KG-Winch-Puller-20-Meter-VPA-GS-CE-TUV/202667237597 None of them seem to have the holding device of the Haltrac, maybe the patent is still in force. Not to difficult to add a cleat or rope stopper in a fixed installation.

If you don't need a huge lift distance the car mount wheelchair hoist layout seems to have quite a lot in its favour although its probably too tedious to use if not power driven. Basically an L shape jib pivoted at the bottom of the long arm with a screw jack running between a joint close the L bend and a strong point a suitable distance above the bottom pivot. Considerable variation in angles and dimensions between the commercial designs. In practical sizes jib end movement gives a maximum lift of around 3 to 4 ft which may not be enough for all purposes. However given an appropriate basic mounting height and a selection of sling lengths with, if need be, a suitable intermediate support such a device should be up to all workshop floor to bench or floor to machine lifting needs.

The hoist is complete, it just needs mounting and power si it has to be marked. If you look at any proper truck mounted crane you will see they are CE marked by the crane manufacturer. an analogy to your view would be that a flat screen TV did not need to be CE marked becaause it had to be mounted on a wall and plugged in. Currently any item that falls under one of the CE directives has to be compliant and CE marked before it is "put into use" even if it is for personal use only. In practice this is not done and it is unlikely that any enforcement action, or even detection would take place for private individuals. What could catch you out is insurance. If you have to make a claim because of an accident or incident caused by a personally imported non-compliant item they could refuse to pay out. This could leave you homeless.

Anyone remember the "Haltrac" midget hoist from years ago constructed from nylon pulleys and thin nylon rope? I bought one 40+ years ago, I still use it, find it invaluable for lifting fairly heavy lumps around my small workshop and it can literally be put into a (largish) pocket. Sadly, they don't seem to be made now, although they do appear on Ebay from time to time. If memory serves, I paid 27/6 for mine.

If anyone does want to mount a plate mount hoist like David posted the pics of, just be sure of your concrete slab. I have seen some that were large in area and 6" to 8" thick. Obviously they would hold a huge bolted plate load if good slab mounting bolts as mentioned were used. However – I've also seen a few that were 1" thick where the owner thought they were 6" thick. The thin slabs would not be safe for a bolted plate load.

" The Declaration of Incorporation is a document which accompanies incomplete machinery and states; this piece of machinery is incomplete and only complies with some parts of the directive. … the manufacturer of the complete machine must ensure it complies with the whole Machinery Directive. "

Realistically the size of trolley to fully exploit the hoist seen in Davids starter post is a car trailer. Single sheet 8 x 4 size sounds about right. Which isn't quite what is wanted

Warwickshire Show, to go or not. New guy from Norway, planning a Bonelle grinder Jekyll’s “Pendulous” Engine c 1870 Is it safe to paint humbrol / revel enamel paint over car spray paint? Diesel Pultra model P M&W Microstat Micrometer What did you do Today 2024 Stuart Dynamo A question of design

The winches known as 'come-alongs ' by the yanks must not be used for lifting, as per their instructions. They lift ok but their mechanism for releasing is not safe and may drop suddenly.

If a private purchaser bought one of these for their own non-commercial use & did not subsequently market or sell it, would they still be required to CE mark it after it was incorporated into their equipment ?

Realistically its made for the American "Good'Ole Boys" truck market so mostly overkill in Britain. We looked at it to mount on a trailer to help loading but dropped the idea as it all got too permanently engineered. Fit when needed being more appropriate.

If a private purchaser bought one of these for their own non-commercial use & did not subsequently market or sell it, would they still be required to CE mark it after it was incorporated into their equipment ?

![]()

So it bis imperative that the fixings are securely fixed to the floor, with ground anchors, such as Rawlbolts, in concrete floors, or with a reinforcing plate beneath a wooden floor.

Another idea for a compact hoist for lifting chucks or work onto a lathe or mill. Lifting capacity would be limited to the size, weight of the lathe or mill and how securely it was mounted.

As the hoist as shown cannot be used as supplied & must be attached to something else to be able to function, it cannot be CE marked and should be supplied with a Declaration of Incorporation ?

Personaly, I would not use it, not because it would be unsafe but because it would take up valuable floor space and prefer a ceiling mounted rail or swing type hoist which has a moving trolley. The truck hoist can only lift and swing in an arc. There is no axial movement to position the load after lifting.

Lots of talk about CE markings and not being covered by insurance which is true. BUT like many posts on this forum, we have wanderred away from the original purpose of this post.which was a way of lifting a chuck or rotary table onto the mill table.

The engine hoist type of lift on rollers does give good flexibility for home shops. No risk of plate mount pulling off the slab with that.

These truck hoists are designed to lift in excess of 400kg. A rotary table or chuck (for home use) would be less than 40kg. The safety factor of it failing is very low. Is it any more dangerous than making your own hoist or using a block and tackle system in your workshop ?

But until it is mounted, it is not functional. It cannot stand up on it's own or be used for any purpose until it has been installed. Only then will it be a functional piece of equipment capable of being tested.

As the hoist as shown cannot be used as supplied & must be attached to something else to be able to function, it cannot be CE marked and should be supplied with a Declaration of Incorporation ?

If you can get hold of one hospitals use a lift designed to lift patients from a bed. They are like a small folding engine crane but very lightweight and easy to store.

As I mentioned in a previous thread a lighter device, hundredweight + capacity or so, on a work cart would seem more appropriate. The work cart giving stability and mobility as well as being useful in its own right. I have a potential design roughed out but am stuck for the cable or strap winder. The inexpensive winches are too big and cumbersome. The crane needs to fold up neatly and not get in the way. A ratchet strap is an appropriate size but those only work one way. What I need is a 1/4 scale or thereabouts come-along.

Somewhere, I have a small ‘tirfor’ type of wire rope hoist/pull-along. Never used it as it was very much lightweight for things I used to do. I thought ig good for 50-100kg, no more.

If the Haltrac is defunct, someone might do the community a service by 'reverse engineering' one and publishing the design. The lock is the clever bit. Along with all sorts of other things, I lifted a Lotus Twin Cam engine, with 200E gearbox attached, several times with mine. Must have been >3cwt. Somewhat hair-raising, given the thinness of the rope. I wonder where I put it…

We have a wheelchair hoist in the back of our Honda Jazz, to load and unload the wife’s mobility scooter, I am very impressed with the quality of the product but it certainly wasn’t cheap, nearly £1800 fitted, it’s a small niche market with few suppliers hence the price.

That form of wheel chair hoist is my fallback layout for the work car mounted crane I really must get round to making. Trouble is there seems no way of making it fold up neatly out of the way. I guess boltng a scaffold pole to one corner of the work cart and fitting the crane to a slightly smaller post so it could just be dropped in place when needed would work. Would swivel just fine. Crane assembly mavbe 2" thick so no big deal to hang on the wall. Screw ing some paving slabs under the bottom of the work cart and being sensible over the load position relative to the cart should cover any balance issues.

We use pillar jib carnes at work. I cannot ask anyone to certify a crane until it has been installed, at which point it is inspected and load tested by a competent person and t a LOLER certificate is issued. Non of the pillar jib cranes in our premises are CE marked, but all are LOLER certified. What makes this piece of equipment any different ?

Anyone remember the "Haltrac" midget hoist from years ago constructed from nylon pulleys and thin nylon rope? I bought one 40+ years ago, I still use it, find it invaluable for lifting fairly heavy lumps around my small workshop and it can literally be put into a (largish) pocket. Sadly, they don't seem to be made now, although they do appear on Ebay from time to time. If memory serves, I paid 27/6 for mine.

The conventional garage type of crane carries nearly all the load on the wheels at the front of the long legs, so is preferable, if space allows.

" The Declaration of Incorporation is a document which accompanies incomplete machinery and states; this piece of machinery is incomplete and only complies with some parts of the directive. … the manufacturer of the complete machine must ensure it complies with the whole Machinery Directive. "

Home › Forums › Workshop Tools and Tooling › Possible machine hoist? This topic has 28 replies, 21 voices, and was last updated 29 March 2020 at 20:40 by Bazyle. Viewing 25 posts - 1 through 25 (of 29 total) 1 2 → Author Posts 1 February 2020 at 08:31 #450168 David George 1Participant @davidgeorge1 Just browsing on the net and on eBay saw thus hoist. I just thought it may be useful to some members at a fairly low cost. It does need a good think about the base load fixing but there are ways round this but I can see it lifting a chuck or rotary table etc. Vidal truck hoist £199.99. Not connected to seller etc. David

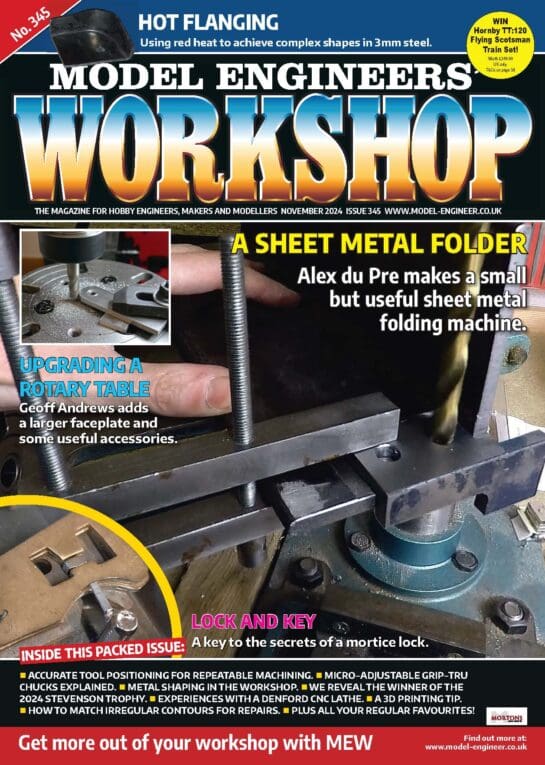

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

Maybe a large base that clamps to the main bed ways like a fixed steady might spread the load to more solid parts of the machine?

Neil

Neil

Neil

Neil