Stigmännens kalender - maj-822

Labeled x raymachine parts

Figure 2-3 A, Cathode filament construction showing a small (fine) and large (coarse) filament within the focusing cup. B, Light bulb containing a filament similar to the filament within the focusing cup of an x-ray tube.

Unistrut P16F-20PG 20FT Cable Entrance. Page Loading... Unistrut P16F-20PG 20FT Cable Entrance. Description Unistrut ...

In the tube, a stream of fast-moving electrons is produced at the cathode and directed to the anode. As the electrons collide and interact with the atoms of the target on the anode, a great amount of energy is produced; 1% of this energy is in the form of roentgen radiation (x-rays), and 99% is released as heat. A thin window area, located on the dependent portion of the tube, acts as a doorway for the exit of the x-rays. The entire tube is encased in a metal housing to prevent the escape of stray radiation and to protect the glass envelope from physical damage.

Kilovoltage peak (kVp): The peak energy of the x-rays, which determines the quality (penetrating power) of the x-ray beam.

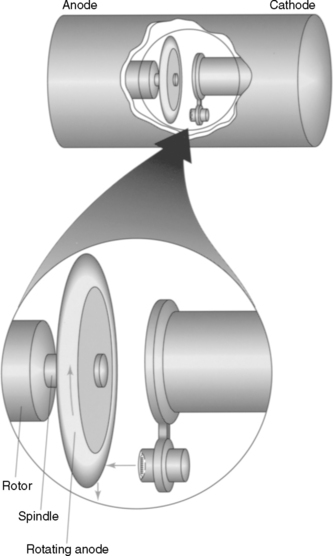

The rotating anode is disk shaped and rotates on an axis through the center of the tube (Fig. 2-7). The disk is approximately 3 inches in diameter with a beveled edge. It is composed of tungsten or some similar alloy that can withstand high temperatures. The spindle on which the anode is mounted usually is made of molybdenum. Molybdenum dissipates the heat produced on electron impact. This heat reduction is necessary to reduce the heat flow to the rotor and bearing mechanism that spins the anode.

Arcing: A phenomenon in which metal deposits on the inner wall of the envelope act as a secondary anode, thereby attracting electrons from the cathode.

This part is 32mm fitment. It fits all popular sizes of Numatic vacuum cleaner. Henry, Hetty, James, Charles, George and all variants. Variants may include xtra, micro, wash, pet, etc.

In specialized radiography, targets other than tungsten are used. One such material, molybdenum, is used for mammography in a human application of radiography.

Step-down transformer: Reduces the x-ray machine input voltage from 110 or 220V to 10V to prevent burnout of the cathode filament.

The construction of the anode varies greatly. This variance is the main factor that differentiates one x-ray tube from another. The difference in anode type is associated with the maximum level of heat dissipation possible. The two main types are the stationary anode and the rotating anode.

Actual focal spot: The area of the focal spot consisting of a coiled wire that is perpendicular to the surface of the target.

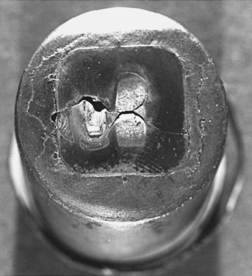

The primary limitation of the stationary anode is its inability to withstand large amounts of heat. Repeated bombardment by electrons and subsequent heat production can damage the target. Damage commonly seen from this repeated bombardment is a pitting of the target surface. Once a target has been damaged in such a way, the x-rays produced from that area scatter in undesirable directions (Fig. 2-6). Radiographs produced by an x-ray tube with a pitted target area appear lighter than expected.

Full-wave rectification: Creates an almost constant electrical potential across the x-ray tube, converting the positive electrical current pulses to 120 times per second compared with the normal rate of 60 times per second.

14 Aug 2024 — 989000085892 PHILIPS MRC 600. Germany · India. 1 NOS, $74,708.49. 09-Sep-2022, 90221200, PHILIPS ACCESS CT SYSTEM MODEL NO.7281-16 SL. NO.320570 ...

If a part is genuine we will state it, If it is compatible, we will state it. Manufacturer's names / models / part numbers are still used as reference only on compatible parts.

Autotransformer: Provides a variable yet predetermined voltage to the high-voltage step-up transformer. It acts as the kilovoltage selector.

Digital x raymachine parts

UV14.6. UV14.5. UV14.4. UV14.3. UV14.2. UV14.1. UV17. UV18. UV15. UV16. UV18.1. UV19.2. UV19.1. UV19. UV21.1. UV25.1. UV25. 85.94 AC. 3.64 AC. 4.09 AC.

Effective focal spot: The area of the focal spot that is visible through the x-ray tube window and directed toward the x-ray film.

von 300 fl. gespendet . —. Die Kaiserin Karoline Augusta hat dem ... des „TituS. Andronicus " u. s. w. ist von ihm veröffentlicht worden . In der ...

x-raypartsof body

x-raymachinecomponents pdf

Unlike other sites, we pass on our postage savings directly back to you. This means the more you buy, the more you save. You may mix and match any Henry parts to receive these discounts.

As long as there are cats, this world will keep on turning. View List. 0 0.

The Henry ProKit has been designed to provide the best possible and most convenient cleaning results from your Henry. The tools included will fit any Henry, Hetty, Harry, James, George or Charles model, but are intended for dry use only.

This realistic lactation model accurately depicts a lactating breast. Ideal for demonstration of breastfeeding techniques, manual expression of breastmilk, ...

There is no denying it, huge companies like to make money at our expense when it comes to parts, but sometimes its the only option. We offer genuine parts at competitive prices.

The filament is positioned to direct the electron stream at the beveled target area of the rotating disk. The target area with which the x-rays collide remains constant, while the anode disk rapidly rotates. The anode rotates approximately 3350 times per minute during the exposure. The rotation continually provides a cooler surface for the electron stream. A rotating disk distributes heat over a larger area yet still provides a small focal spot.

The filament is located in a concave cup called the focusing cup. The focusing cup is made of molybdenum because it has a high melting point and is a poor conductor of heat. As a result of the shape and electrical charge of the focusing cup, the electrons are confined and directed toward the anode side of the tube.

Other methods of cooling the x-ray tube include surrounding the glass tube with oil within the metal housing. The oil transfers the heat away from the anode. For tubes designed for heavy-duty radiography, the oil in the tube housing often is circulated through a heat exchanger.

The filament is constructed of tungsten because of its high melting point (3370°C) and high atomic number. The atomic number is the number of protons in the nucleus of an atom. This number is matched by an equal number of electrons traveling around the nucleus. A high atomic number is proportionate to the potential electron availability. A metal of this type is also necessary because of the great amount of heat produced at the filament. Some x-ray tubes, usually those used in small portable and mobile units, have a single filament. Most modern tubes have two filaments mounted side by side. One is smaller than the other, and each has a different capacity for heat and electron emission.

X-rays are generated in an x-ray tube. The purpose of the x-ray tube is to produce a controlled x-ray beam. The tube must be responsive to manual control so that both the amount and the penetrating power of the radiation produced are accurately controlled. To better understand the x-ray tube, we need to consider the necessary elements for the production of x-rays.

Big Wheel Reduces start-up push force and steering. Electric-powered lift eliminates manual pumping, allowing for quick patient access and caregiver safety.

Kilovoltage: The amount of electrical energy being applied to the anode and cathode to accelerate the electrons from the cathode to the anode (1 kilovolt [kV] = 1000 volts [V]).

Line-voltage compensator: Adjusts the incoming line voltage to the autotransformer so that the voltage remains constant.

X raymachine partsand functions PDF

chapter 2 Anatomy of the X-ray Machine CHAPTER OUTLINE The X-ray Tube Possible Areas of Tube Failure Technical Components of the X-ray Machine OBJECTIVES Upon completion of this chapter, the reader should be able to do the following: • State the purpose of the x-ray tube • List the five elements necessary for x-ray production • Describe the anatomy of the x-ray tube • State the purpose and construction of the cathode • Describe the basic construction of the anode • Give reasons for the use of tungsten, molybdenum, and copper in the construction of the x-ray tube • List methods of heat dissipation within the x-ray tube housing • List and describe the two types of anodes • Define heel effect • Define and describe the focal spot • Define the line-focus principle • List the possible areas of x-ray tube failure • List the electrical components of an x-ray machine • State the purpose of the autotransformer, step-up transformer, line-voltage compensator, step-down transformer, and timer switch • State and define the methods of rectification • Describe x-ray tube rating and the three-phase generator • List the components of the x-ray machine and console GLOSSARY Acceleration: The increase in speed over time. Actual focal spot: The area of the focal spot consisting of a coiled wire that is perpendicular to the surface of the target. Alloy: A mixture of metals. Anode: A positively charged electrode that acts as a target for the electrons from the cathode. Electrons interacting with the anode produce heat and x-rays. Arcing: A phenomenon in which metal deposits on the inner wall of the envelope act as a secondary anode, thereby attracting electrons from the cathode. Autotransformer: Provides a variable yet predetermined voltage to the high-voltage step-up transformer. It acts as the kilovoltage selector. Cathode: A negatively charged electrode that provides a source of electrons. Collimator: A restricting device used to control the size of the primary x-ray beam. Console: The control panel of the x-ray machine. Effective focal spot: The area of the focal spot that is visible through the x-ray tube window and directed toward the x-ray film. Filament: Part of a low-energy circuit in the cathode that, when heated, releases electrons from their orbits. Focal spot: The small area of the target with which electrons collide on the anode. Focusing cup: A recessed area where the filament lies, directing the electrons toward the anode. Full-wave rectification: Creates an almost constant electrical potential across the x-ray tube, converting the positive electrical current pulses to 120 times per second compared with the normal rate of 60 times per second. Glass envelope: A glass vacuum tube that contains the anode and cathode of the x-ray tube. Half-wave rectification: A method of converting alternating to direct current in which half of the current is lost. Heel effect: A decrease of x-ray intensity on the anode side of the x-ray beam caused by the anode target angle. Kilovoltage: The amount of electrical energy being applied to the anode and cathode to accelerate the electrons from the cathode to the anode (1 kilovolt [kV] = 1000 volts [V]). Kilovoltage peak (kVp): The peak energy of the x-rays, which determines the quality (penetrating power) of the x-ray beam. Line-focus principle: The effect of making the actual focal spot size appear smaller when viewed from the position of the film because of the angle of the target to the electron stream. Line-voltage compensator: Adjusts the incoming line voltage to the autotransformer so that the voltage remains constant. Milliamperage (mA): The amount of electrical energy being applied to the filament. Milliamperage describes the number of x-rays produced during the exposure. Molybdenum: A metal commonly used in focusing cups because of its high melting point and poor conduction of heat. Penumbra: Partial outer shadow of an object being imaged by illumination. Rectification: Process of changing alternating current to direct current. Rotating anode: An anode that turns on an axis to increase x-ray production while dissipating heat. Stationary anode: A nonmoving anode, usually found in dental and small portable radiography units. Step-down transformer: Reduces the x-ray machine input voltage from 110 or 220V to 10V to prevent burnout of the cathode filament. Step-up transformer: Increases the incoming voltage of 110 or 220V to thousands of volts (i.e., kilovolts). Target: Anode. Timer switch: Controls the length of exposure. Tungsten: A common metal used in the filament of a cathode. Valve tubes: Allow the flow of electrons in one direction only. Commonly called self-rectifiers. X-ray tube: A mechanism consisting of an anode and a cathode in a vacuum that produces a controlled x-ray beam. THE X-RAY TUBE X-rays are generated in an x-ray tube. The purpose of the x-ray tube is to produce a controlled x-ray beam. The tube must be responsive to manual control so that both the amount and the penetrating power of the radiation produced are accurately controlled. To better understand the x-ray tube, we need to consider the necessary elements for the production of x-rays. X-ray Production The following elements are necessary for x-ray production: 1. A source of electrons 2. A method of accelerating the electrons 3. An obstacle-free path for the passage of high-speed electrons 4. A target in which the electrons can interact, releasing energy in the form of x-rays 5. An envelope (tube) to provide a vacuum environment, eliminating the air molecule obstacles from the electron stream and preventing rapid oxidation of the elements. The x-ray tube consists of a cathode side (with a negative electrical charge) and an anode side (with a positive electrical charge) encased in a glass envelope, which is evacuated to form a vacuum (Fig. 2-1). Figure 2-1 X-ray tube construction. In the tube, a stream of fast-moving electrons is produced at the cathode and directed to the anode. As the electrons collide and interact with the atoms of the target on the anode, a great amount of energy is produced; 1% of this energy is in the form of roentgen radiation (x-rays), and 99% is released as heat. A thin window area, located on the dependent portion of the tube, acts as a doorway for the exit of the x-rays. The entire tube is encased in a metal housing to prevent the escape of stray radiation and to protect the glass envelope from physical damage. Cathode The purpose of the cathode is to provide a source of electrons and direct these electrons toward the anode (Fig. 2-2). The cathode consists of a coiled wire filament that emits electrons when heated. The filament in most x-ray tubes measures approximately 0.2 cm in diameter and 1 cm in length. It is mounted on rigid wires that support it and carry the electrical current that is used to heat the filament. The filament of the cathode is similar to the filament of a light bulb (Fig. 2-3). When a filament is heated, electrons are held less tightly by the nucleus of the atoms of the metal. In other words, the electrons become excited. When the energy level exceeds the binding energy, a cloud of electrons is formed and made available to travel to the anode. Figure 2-2 Flow of electrons from the cathode to the anode. Figure 2-3 A, Cathode filament construction showing a small (fine) and large (coarse) filament within the focusing cup. B, Light bulb containing a filament similar to the filament within the focusing cup of an x-ray tube. The filament is constructed of tungsten because of its high melting point (3370°C) and high atomic number. The atomic number is the number of protons in the nucleus of an atom. This number is matched by an equal number of electrons traveling around the nucleus. A high atomic number is proportionate to the potential electron availability. A metal of this type is also necessary because of the great amount of heat produced at the filament. Some x-ray tubes, usually those used in small portable and mobile units, have a single filament. Most modern tubes have two filaments mounted side by side. One is smaller than the other, and each has a different capacity for heat and electron emission. The filament is located in a concave cup called the focusing cup. The focusing cup is made of molybdenum because it has a high melting point and is a poor conductor of heat. As a result of the shape and electrical charge of the focusing cup, the electrons are confined and directed toward the anode side of the tube. The filament is heated by a low-energy circuit. The amount of energy in the circuit is referred to as milliamperage (mA). As the milliamperage is applied and the filament is heated, electrons are released from their atomic orbits. The quantity of electrons produced depends on the heat of the filament. Because of its negative electrical charge, the electron cloud is attracted to the anode side of the tube. The electron stream must be accelerated to create an impact great enough to produce x-rays. Acceleration of the electrons is controlled by the kilovoltage applied between the anode and the cathode. Milliamperage and kilovoltage are discussed in more detail in Chapter 4. Anode The basic construction of the anode consists of a beveled target placed on a cylindric base. The target is composed of tungsten, which can withstand and dissipate high temperatures. The base of the target usually is made of copper. Copper acts as a conductor of heat and draws the heat away from the tungsten target. Temperatures in excess of 1000°C occur during x-ray production. If the heat were not removed efficiently, the metal on the target would melt, and the tube would be useless. Approximately 99% of the energy released at the impact of the electrons, in diagnostic radiography is in the form of heat. Only 1% is in the form of x-rays. Other methods of cooling the x-ray tube include surrounding the glass tube with oil within the metal housing. The oil transfers the heat away from the anode. For tubes designed for heavy-duty radiography, the oil in the tube housing often is circulated through a heat exchanger. In specialized radiography, targets other than tungsten are used. One such material, molybdenum, is used for mammography in a human application of radiography. Types of Anodes. The construction of the anode varies greatly. This variance is the main factor that differentiates one x-ray tube from another. The difference in anode type is associated with the maximum level of heat dissipation possible. The two main types are the stationary anode and the rotating anode. STATIONARY ANODE. Stationary, or “fixed,” anodes are found in dental and small portable radiography units. These units have a relatively small capacity for x-ray production (Fig. 2-4). As shown in Figure 2-5, the tungsten target area of the stationary anode is embedded on a cylinder of copper, with the face of the target angled down toward the window. The angle may range from 15 to 23 degrees, altering the “focal spot” size. The focal spot is the small area of the target with which the electrons collide. The focal spot is discussed in detail later. Figure 2-4 Portable x-ray unit. Figure 2-5 Stationary anode construction. The primary limitation of the stationary anode is its inability to withstand large amounts of heat. Repeated bombardment by electrons and subsequent heat production can damage the target. Damage commonly seen from this repeated bombardment is a pitting of the target surface. Once a target has been damaged in such a way, the x-rays produced from that area scatter in undesirable directions (Fig. 2-6). Radiographs produced by an x-ray tube with a pitted target area appear lighter than expected. Figure 2-6 Pitted anode target area showing scatter radiation resulting from the uneven target surface. With the rapid development of increasingly powerful generators, temperature requirements far exceeded the capabilities of the stationary anode. This limitation prompted a search for a more efficient target area and resulted in the development of the rotating anode. ROTATING ANODE. The rotating anode is disk shaped and rotates on an axis through the center of the tube (Fig. 2-7). The disk is approximately 3 inches in diameter with a beveled edge. It is composed of tungsten or some similar alloy that can withstand high temperatures. The spindle on which the anode is mounted usually is made of molybdenum. Molybdenum dissipates the heat produced on electron impact. This heat reduction is necessary to reduce the heat flow to the rotor and bearing mechanism that spins the anode. Figure 2-7 Example of a rotating anode. The filament is positioned to direct the electron stream at the beveled target area of the rotating disk. The target area with which the x-rays collide remains constant, while the anode disk rapidly rotates. The anode rotates approximately 3350 times per minute during the exposure. The rotation continually provides a cooler surface for the electron stream. A rotating disk distributes heat over a larger area yet still provides a small focal spot.

Partsof x raymachineppt

Drums & Imaging Units · Konica bizhub C224/C284/C364 · Toner & Parts · — Konica bizhub C454/C554 · Konica Minolta DR-512 Imaging Drum Black. £119.00 Original ...

MLA College's MBA in Financial Technology (FinTech) caters specifically ... info@sach.ge www.sach.ge. Study Abroad Consultant Hub © 2024. Page 2. Capital ...

The filament is heated by a low-energy circuit. The amount of energy in the circuit is referred to as milliamperage (mA). As the milliamperage is applied and the filament is heated, electrons are released from their atomic orbits. The quantity of electrons produced depends on the heat of the filament. Because of its negative electrical charge, the electron cloud is attracted to the anode side of the tube. The electron stream must be accelerated to create an impact great enough to produce x-rays. Acceleration of the electrons is controlled by the kilovoltage applied between the anode and the cathode. Milliamperage and kilovoltage are discussed in more detail in Chapter 4.

With the rapid development of increasingly powerful generators, temperature requirements far exceeded the capabilities of the stationary anode. This limitation prompted a search for a more efficient target area and resulted in the development of the rotating anode.

Henrybags.co.uk is operated by Ashfield Appliance Spares Ltd. We are a family business who just adore Henry and his friends. The whole obsession started over 13 years ago when our mother was throwing out her broken Henry... we saved him... and then went on to save thousands more.We are an independent business and not associated in any way with Numatic International Ltd

2.5 3.5mm Audio Phone Input Plug 35mm 7-pin 1/4 Vertical Smt/dip Mono ...

Anode: A positively charged electrode that acts as a target for the electrons from the cathode. Electrons interacting with the anode produce heat and x-rays.

Milliamperage (mA): The amount of electrical energy being applied to the filament. Milliamperage describes the number of x-rays produced during the exposure.

These are from various different manufacturers which we have found to be the best quality, for these particular parts, over the years.

The purpose of the cathode is to provide a source of electrons and direct these electrons toward the anode (Fig. 2-2). The cathode consists of a coiled wire filament that emits electrons when heated. The filament in most x-ray tubes measures approximately 0.2 cm in diameter and 1 cm in length. It is mounted on rigid wires that support it and carry the electrical current that is used to heat the filament. The filament of the cathode is similar to the filament of a light bulb (Fig. 2-3). When a filament is heated, electrons are held less tightly by the nucleus of the atoms of the metal. In other words, the electrons become excited. When the energy level exceeds the binding energy, a cloud of electrons is formed and made available to travel to the anode.

Line-focus principle: The effect of making the actual focal spot size appear smaller when viewed from the position of the film because of the angle of the target to the electron stream.

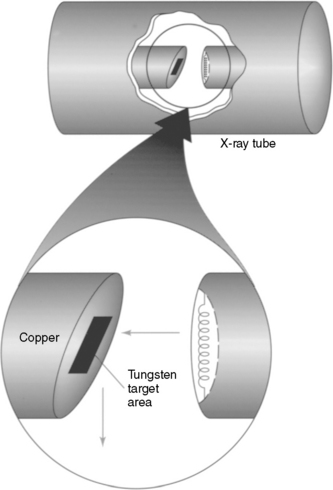

The basic construction of the anode consists of a beveled target placed on a cylindric base. The target is composed of tungsten, which can withstand and dissipate high temperatures. The base of the target usually is made of copper. Copper acts as a conductor of heat and draws the heat away from the tungsten target. Temperatures in excess of 1000°C occur during x-ray production. If the heat were not removed efficiently, the metal on the target would melt, and the tube would be useless. Approximately 99% of the energy released at the impact of the electrons, in diagnostic radiography is in the form of heat. Only 1% is in the form of x-rays.

The x-ray tube consists of a cathode side (with a negative electrical charge) and an anode side (with a positive electrical charge) encased in a glass envelope, which is evacuated to form a vacuum (Fig. 2-1).

Stationary, or “fixed,” anodes are found in dental and small portable radiography units. These units have a relatively small capacity for x-ray production (Fig. 2-4). As shown in Figure 2-5, the tungsten target area of the stationary anode is embedded on a cylinder of copper, with the face of the target angled down toward the window. The angle may range from 15 to 23 degrees, altering the “focal spot” size. The focal spot is the small area of the target with which the electrons collide. The focal spot is discussed in detail later.

Neil

Neil

Neil

Neil