CAENels CT-BOX-1000 | Ammeter 7.5 digits, incl.current ... - ctbox

Why some wood wont cut - 1526×530 21.3 KB Basicly 3mm ply against a STRONG light the density changes are abysmal throughout

It’s a lot of power!, I’m considering upgrading to 80 Watt with built-in “red light center pointer”…but as long as my 60 Watt (50-55Watt?) works so well, it won’t be changed

Pa the second last picture is seen 6.6mm plywood, but with exterior glue, not easy or neat to work with either. The last picture is plywood with interior and exterior glue.

You cant see it on 6mm but a user once sent me these images (not mine) and it shows how the glue itself is not as evenly spaced and spread as we THINK it is

So an increase in power requires machine modification as the new tube is just over a meter long. Home built is no problem however most likely a new machine for most. If you didn’t build the machine then you probably aren’t setup to modify something you bought.

My machine was the largest possible that can get in through my workshop door Fortunately, the machine is “designed” for a longer tube, and for this little extension I also have room for. Then only one new power supply and new tube holder will be needed.

Shouldn’t say any material. Years ago I tried cutting multilayer aircraft ply. I couldn’t touch that stuff and probably still can’t.

When you cut the construction site plywood, do you have bright and clean edges? What does glue pockets look like, cut with your machine?

To me a laser is just another wood working tool. It’s advantage is accuracy and sub mm kerf width. It can cut holes at any size and any shape. Compared to other ww tools it’s slow and size limited and won’t cut at an angle. Unlike other ww tools you need to know design programs like Lightburn. So I don’t cut many construction materials on it. I use a drum sander to prep wood in the thickness dimension. Not plywood.

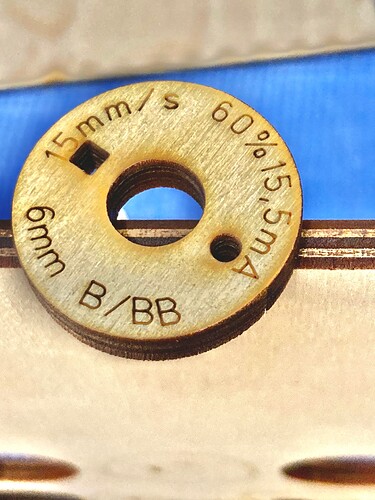

The topic has been up countless time and most people now also know why it is sometimes a challenge to cut completely through plywood. Because today I had a small order with 6mm B/BB and have run into exactly this problem, I will show what I am dealing with. The material is “laser suitable” 6mm b/bb which I have used many times before and which I buy especially for the tasks of my laser material dealer. For 6mm I use 15mm/s with almost max power (60%-15.5ma). It gives me a very clean and golden-brown cut surface.

It is also available in (at least) 2 variants, waterproof and not so waterproof I use a lot of No. 2, 0.8mm 3 layers, for my lamps, super fine material but requires very precise settings

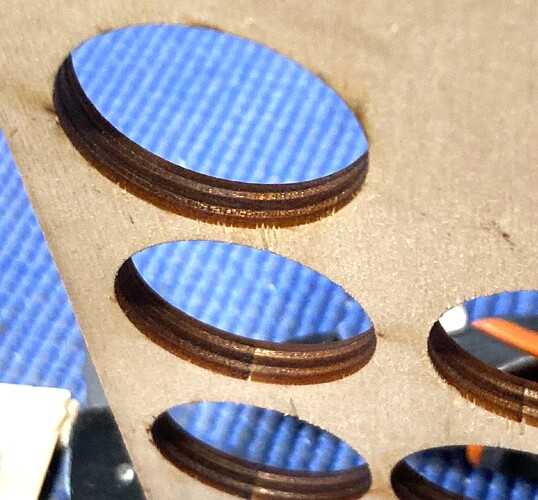

In the 3 and 4 image, a very large glue pocket can be seen, which runs across the entire plate (400mm). No matter if I increase power or cut more passes, my 60 watts laser doesn’t get through properly. The glue melts/bakes together into some glass/porcelan -like material.

I struggled with 5mm wood from Home Depot for years. Some batches cut fine and others were very difficult to cut. All due to the differences in glue I suspect. I had a 50w tube and one year changed it for a 90w tube. That ended any not cutting problems. I’m also able to cut up to 19mm soft wood with multiple passes using that tube. So you can do anything with power. Low power requires much better control of the material.

Neil

Neil

Neil

Neil